Busy construction companies need reliable equipment to deliver quality work on budget and on schedule. Paul Battista, founder and CEO of Brothers Paving and Concrete, knows firsthand that staying on top of planned maintenance. Performing repairs quickly on critical assets is key for any company that wants to compete effectively. In March 2018, Brothers implemented MPulse to streamline maintenance operations. At the same time, Brothers invested in NexTraq vehicle and asset tracking software, and IIoT that drives vehicle maintenance improvement. This software uses GPS technology in vehicles to help fleet managers track mobile assets and monitor driver behavior.

IIoT Software Integration

Both software platforms offered big advantages to Brothers. However, the company realized it could get even more value by integrating the two solutions. By doing so, the maintenance team could trigger work orders automatically. As a result, they could get trucks in from the field for maintenance on a more reliable schedule—one driven by actual mileage, not driver-reported mileage or time intervals.

The MPulse-NexTraq Industrial Internet of Things (IIoT) integration enables tire rotations, oil changes, lubrication, and other critical maintenance activities to get done when they should. As a result, the company reduced its breakdowns due to overdue maintenance. It also keeps low-mileage equipment in the field and working, instead of sitting in the shop for maintenance that isn’t yet necessary.

Brothers was able to use MPulse DataLink Integration Adapter to easily map to NexTraq mileage data to the mileage fields in MPulse. And with that data coming in automatically, MPulse could trigger work orders and notify drivers when vehicles needed to come in for scheduled maintenance.

“It just took a phone call to MPulse,” said Dorthy Battista, Brothers fleet manager. “It was such a smooth process, which kind of surprised me. I’d heard so many integration horror stories, but this was really easy.”

Benefits for the Maintenance Team

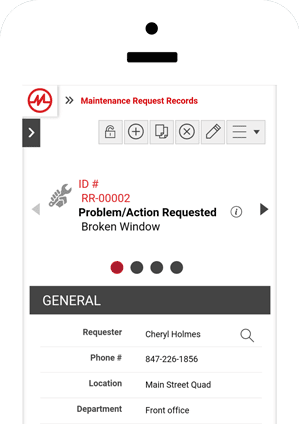

MPulse CMMS software helps maintenance managers organize and make sense of what to do with large volume of data gathered by IIoT devices. That enables maintenance teams to take action when conditions on assets show problems or when the assets need routine maintenance.

“The biggest benefit for us is not having to worry about the mileage because the data is automatically updated,” Dorthy Battista said. “I don’t have to trust the driver to tell me when a vehicle needs an oil change. I can sleep at night knowing my trucks are going to be maintained.”

Learn more about how MPulse integrates with other software. Contact us.