In business as in life, using anything other than complete, accurate data to make decisions can be both dangerous and costly.

MPulse founder Steve Brous coined a term around it—”experitive.” A combination of “experiential” and “intuitive,” it describes a form of decision-making that relies on instinct instead of data. In reality, it often means working with no data.

Steve strongly believed this kind of decision-making is less than optimal. Sometimes it gets you the results you’re looking for. However, without consistently good data, a business can’t make consistently good decisions. And without the ability to make sound decisions, a business can’t produce consistently good results.

Ultimately, only data-driven decisions can drive the results necessary for your business to thrive and grow. Consider the following example.

Table of Contents

A Man Walks into a Bar…

…or rather, an employee, Dave, walks into the cold storage area of Sam’s Saloon and thinks, “I can save the bar some money by upgrading the old storeroom refrigeration condenser.” Based on the energy rating of the system’s compressor, it keeps the storage area cooled for about $400 per month. Dave knows the condenser is getting old, likely leaking, and probably not living up to its original performance potential. How can he make the case to Sam that the bar is wasting money unnecessarily so he can buy a new condenser? If the purchase is approved, how will he prove to Sam that the investment is paying off?

Dave could take two routes to prove his point:

The Experitive Route

Dave tells Sam, “I can save you lots of money,” but doesn’t say exactly how much. The new condenser (hopefully) gets approved and purchased. Through observation, Dave proclaims, “Seems better to me!” This might sound crazy, but it’s often how maintenance decisions are made—usually because people don’t think they can measure results or don’t understand how.

The Data-Driven Route

Dave installs a meter to monitor and measure energy consumption by the system. He discovers it’s actually costing $600 a month—$200 more than it should. He can now clearly back up his claim with numbers and get his purchase request approved.

With a new condenser installed and energy usage back to what it should be, Dave is generating $200 per month in savings. That will pay for the new $1,000 condenser in five months and add $200 to Sam’s bottom line every month thereafter.

But the benefits don’t end there. Dave can continue to monitor usage from now on. If it climbs back above $400, he can quickly fix the problem and avoid future waste.

Having hard numbers not only helps you run your business, but it also allows you to measure and use a whole host of key performance indicators. It provides the ability to say, for example, “We were 12,000 kilowatt hours over our mean monthly energy consumption” instead of “Boy, looks like we used lots of energy this month.” With solid metrics, you can accurately assess the cost-effectiveness of any new equipment installations or facility improvements.

Data-Driven Decision are as Easy (and Accurate) as One, Two, Three

Sam’s Saloon provides a simplified example, but the power of good data increases exponentially if you’re using a CMMS. A modern CMMS solution will allow you to collect and report on data across your entire asset inventory, providing numerous measures to help you make better decisions and answer business-critical questions. Many contemporary CMMS solutions allow you to connect to meters and gauges directly, eliminating the need for meter readings and manual data entry.

Even simple measures from work order records can provide powerful data. Consider another example: You might wonder, “How much am I spending on maintenance for each of my work order types?”

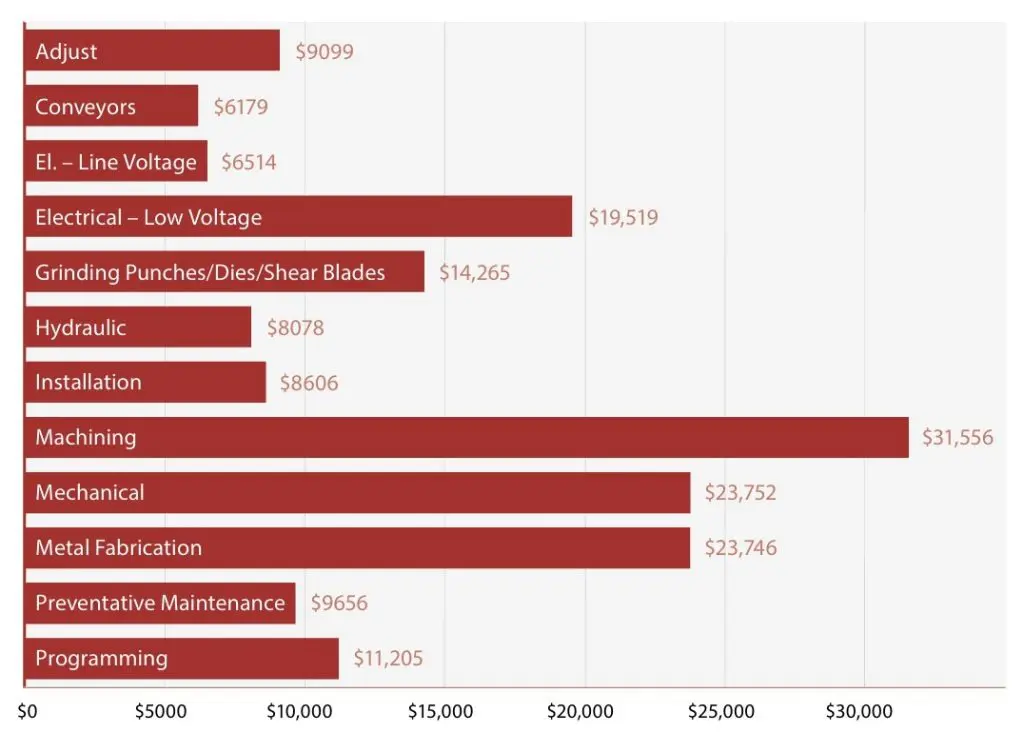

The following graph answers this question.

You can easily generate this type of report from a CMMS. At a glance, you’ll know exactly how much money each work order type is costing your business in maintenance for a specified timeframe (in this example, a year), and certain questions can be quickly answered:

- What type of maintenance do I spend the most on?

- How does the cost of preventive maintenance compare to repair costs?

- If I run this report for a different time period, like last year, are there significant changes by category?

Beyond general questions, you can formulate precise questions that lead to a more informed, data-driven decision-making process:

- Why are my machining maintenance costs so high?

- Do I need to purchase any new equipment?

- How much will the new equipment cost compared to the current maintenance expense?

- Will I save money over time by purchasing new equipment? How much?

CMMS gives you accurate, complete data, and you can apply this data directly to purchasing or other important organizational decisions.

Support Your Decisions with Numbers

Don’t rely on intuition alone for your critical business decisions. Begin to ask yourself whether it’s possible to support your decisions with numbers. Then, identify opportunities where these numbers can inform your decision-making process.

Finally, consider implementing a modern CMMS to help you gather complete and accurate data. You’ll quickly see the results in the most important place of all—your bottom line.

To learn more about data-driven maintenance and some of the powerful, affordable tools that make it easy, contact MPulse today for a free demo at (800) 944-1796.