Scheduled Maintenance That Actually Prevents Problems

When equipment breaks down, work stops, money is lost, and people get frustrated. That’s why many companies schedule maintenance tasks to take care of equipment before it breaks. But planning and tracking that work can get complicated. CMMS and scheduled maintenance prevent problems by helping your team plan, document, and track maintenance work. It makes sure the right tasks happen at the right time, and it keeps everyone organized. What Is Scheduled Maintenance? Scheduled maintenance is the practice of doing regular check-ups on equipment so problems don’t have a chance to grow. Instead of waiting for something to break, maintenance teams check equipment and other assets early, replace worn parts, and make adjustments before things go wrong. You prevent the problem by staying ahead of it. Some common scheduled maintenance tasks include: These tasks may seem simple. But skipping them can lead to expensive breakdowns in the future. CMMS can remind you when something needs to be done. Often, problems happen because maintenance teams don’t have a good system to keep track of everything. They may forget tasks, lose paperwork, or miss an important warning sign. Sometimes maintenance teams are so busy fixing emergencies that they don’t have time to focus on routine work. That means more downtime, more repair costs, and more stress for everyone. How CMMS Helps Prevent Real Problems CMMS prevents many of the issues that make scheduled maintenance difficult. It keeps all maintenance information in one place and makes it easy for teams to stay organized. Here are some ways CMMS software and scheduled maintenance work together to prevent problems. 1. Automated Reminders CMMS sends alerts when it’s time to do a task. No one has to remember dates or search through paperwork. The system tells workers what needs to be done and when. 2. Easy-to-Follow Work Orders Work orders explain what task needs to happen, where it is, what tools are needed, and how long it should take. CMMS organizes all of this data so maintenance teams can follow clear instructions. 3. Real-Time Updates When a technician finishes a task, they can check it off in CMMS right away, even from a phone or tablet in the field. This capability keeps everyone up to date, including managers who want to see what’s been completed. 4. Data That Helps You Make Better Decisions CMMS tracks the history of each piece of equipment. Over time, it shows patterns like how often an asset breaks down or which parts wear out the fastest. This information helps teams choose the best time to replace equipment, order parts early, and prevent failures. 5. Less Paperwork, Less Stress Instead of storing piles of binders, clipboards, and sticky notes, CMMS keeps everything electronically. It’s easier to find information, and nothing gets lost. The Benefits of Scheduled Maintenance Done Right When scheduled maintenance is supported by a CMMS, everyone benefits. What Makes a CMMS Effective? Not all CMMS programs are the same, but the best ones share a few important features: Scheduled maintenance software doesn’t have to be complicated to work well. In fact, simple systems are often the most effective because people are more likely to use them every day. Getting Started with CMMS and Scheduled Maintenance If your team is new to scheduled maintenance or wants to improve its current system, starting with CMMS is a smart step. Begin by entering your equipment list, setting up basic preventive tasks, and scheduling reminders. Over time, you can add more details, track performance, and fine-tune your maintenance plans. You don’t have to fix everything at once. Even small changes, like doing regular inspections or tracking tasks electronically, can prevent big problems later. Scheduled Maintenance Prevents Problems Scheduled maintenance works best when it’s organized, consistent, and supported by good tools. CMMS makes this possible by turning simple reminders and tasks into a complete system for keeping equipment healthy. When used well, it helps companies avoid breakdowns, reduce costs, and stay productive. In the end, scheduled maintenance isn’t just about fixing machines. It’s about preventing problems before they happen. CMMS is one of the best ways to make that happen. Get started today. Contact us.

Top Three CMMS Platforms Right Now

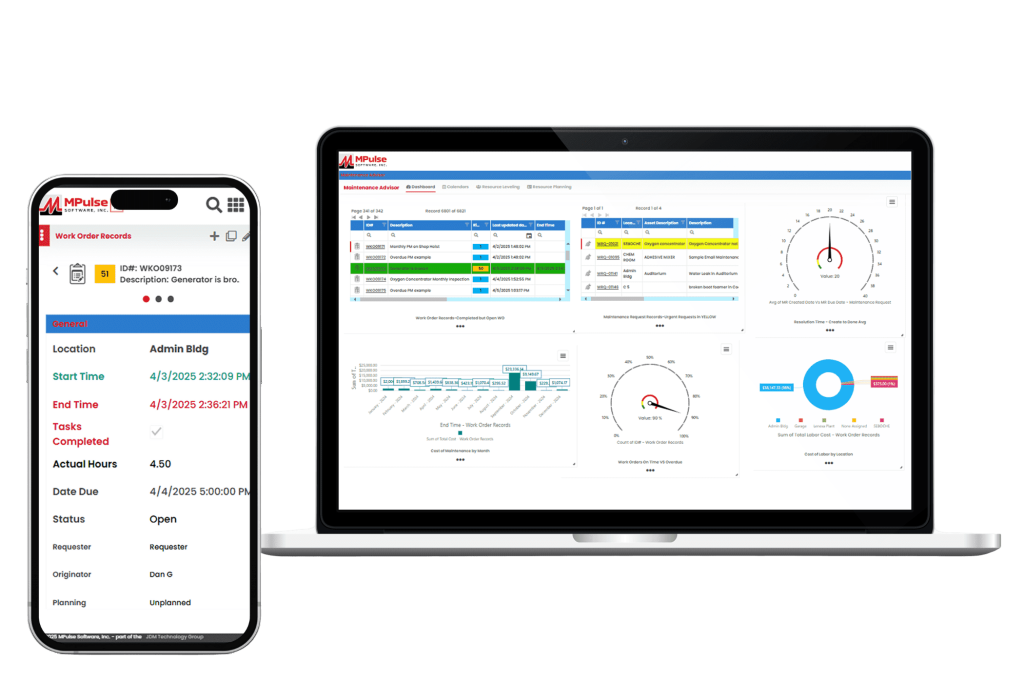

If you’re shopping for CMMS software, narrowing the field to three solid contenders makes the decision a lot easier. These top three CMMS platforms each bring different strengths to the table. Which one you pick depends on whether you prioritize depth of features, ease of use, or speed of adoption. Let’s walk through what each does best, who it’s best for, and the pricing highlights you’ll want to know. #1: MPulse CMMS MPulse positions itself as a mature CMMS for teams that need comprehensive preventive maintenance scheduling, detailed work-order workflows, inventory and vendor tracking, and strong reporting. Additionally, the product emphasizes adaptability across devices and offers tiered packages that scale from small teams to enterprise setups. MPulse also highlights a long track record and thousands of customers using its platform. On pricing, MPulse publishes a Professional edition price point intended for small to midsized organizations. Their published per-concurrent-user figure is intended as a baseline though enterprise needs. MPulse provides implementation and training services designed to streamline and accelerate the rollout process. If you have complex equipment hierarchies, compliance reporting needs, or want deeper labor and vendor controls, MPulse is built for that flexibility. Who Should Consider MPulse MPulse is a great choice for facilities or manufacturing teams that need tried-and-true CMMS capabilities and good software support. Customers are typically ready to invest in configuration, training, and reporting to squeeze operational gains. #2: Limble Limble focuses on making maintenance simple and fast for teams that want mobile apps, dashboards, and asset histories. Limble often touts itself as highly rated for ease of use and places emphasis on unlimited assets and user-friendly work order management. These features can help small to medium teams adopt quickly and get measurable uptime wins. Pricing for Limble includes tiered plans (including a Standard plan in the low-to-mid tens of dollars per user per month and higher tiers for expanded inventory, analytics, and advanced features). They also provide a calculator to estimate pricing based on user counts and required modules. #3: MaintainX MaintainX is built around the frontline user: quick work-order creation from mobile devices, checklists and SOPs for technicians, QR/barcode scanning for assets, and simple inventory controls. Lately MaintainX has emphasized AI-driven suggestions to help reduce unplanned downtime, alongside a limited freemium model that lets small teams start for free and upgrade as needs grow. MaintainX’s pricing structure includes a free/basic tier and paid plans that add preventive maintenance scheduling, condition-based triggers, and expanded parts and permissions features. That makes it suitable for smaller sites, multi-location franchises, or operations teams that want a modern interface and lower friction to get started. The Right CMMS for Your Team The right CMMS depends on factors such as your team size, the complexity of your assets, your available budget, and how quickly you need to see results. A small maintenance crew managing a handful of critical machines will have very different priorities than a multi-site operation with thousands of assets and a dedicated reliability team. To make the evaluation process manageable, start by identifying your top three “must-have” capabilities. These should be the features that directly impact your day-to-day operations. For example, the ability to set preventive maintenance schedules, track and control spare-parts inventory, or ensure technicians can access work orders offline when connectivity is limited. Once those priorities are clear, schedule short demos with each vendor and keep the focus tightly on those use cases. This approach helps you see how the system performs in the areas that matter most. Have questions? We can help. Contact us.

Facility Maintenance KPIs to Track in CMMS

Tracking the right facility maintenance KPIs in your CMMS helps you measure performance, reduce downtime, control costs, and keep your operations running smoothly. When you purchase or upgrade your CMMS, you expect things to improve. Maybe you want faster repairs, fewer breakdowns, or better tracking. But how do you know if the upgrade is actually working? The answer is simple: you measure it. CMMS helps you understand what’s going well, where you need to improve, and how your facility is performing over time. These metrics give you real numbers that you can use to make better decisions and keep your team on the right path. Below are the key CMMS KPIs facility managers should focus on right after implementation. Core Facility Maintenance KPIs After your CMMS purchase or upgrade, you want to focus on three core maintenance metrics: Mean Time to Repair (MTTR), asset uptime, and work order completion rates. These facility performance indicators help you understand the basics of how well your maintenance program is working day to day. Mean Time to Repair (MTTR) MTTR measures the average time it takes to repair equipment once it breaks down. A lower MTTR means your team is fixing issues faster. If your new CMMS improves scheduling, communication, or access to documentation, you should see MTTR go down within the first few months. If it doesn’t, that might mean your workflows need more fine-tuning or your team needs additional training. Asset Uptime Asset uptime tracks how often your equipment is up and running compared to when it is down. High uptime means your critical systems (i.e., HVAC units, production machines, or building controls) are available when you need them. After upgrading your CMMS, one of the first things you should notice is better visibility into preventive maintenance schedules. Watching this KPI should help prevent breakdowns and increase uptime overall. Work Order Completion Rate This KPI shows how many work orders are being completed on time. If your CMMS offers improved mobile access, automated alerts, or easier data input, your completion rate should rise. A high on-time completion rate means your maintenance team is staying organized and responding quickly to requests. It also shows that your CMMS is helping your team work more efficiently. Efficiency and Utilization Maintenance Metrics Once you have a good handle on the core KPIs, the next step is to look at how efficiently your team is working. These maintenance metrics reveal whether your resources, time, and equipment are being used effectively. Technician Productivity Technician productivity measures how much work each technician is completing. CMMS should make it easier for technicians to receive assignments, find instructions, and update progress. After implementation, look for an increase in the number of tasks completed per technician or a decrease in time spent moving between jobs. Scheduled vs. Reactive Work Every facility aims to increase scheduled maintenance and reduce emergency repairs. Tracking the percentage of planned work versus reactive work gives you a clear picture of the stability of your maintenance program. CMMS should shift your team toward more preventive work, which usually costs less and takes less time in the long run. Inventory Turnover If your CMMS includes inventory tracking, this KPI helps you understand how often parts and supplies are used and restocked. Strong turnover means you’re keeping the right amount of inventory, not too much and not too little. This KPI is especially important if you manage a large stockroom or want to prevent delays caused by missing parts. CMMS Cost and Sustainability Indicators Your facility performance indicators should also include metrics that track costs and environmental impact. These numbers help you make smart budget decisions and support sustainability goals. Maintenance Cost per Asset This KPI shows how much you’re spending to maintain each asset. It includes labor, parts, and time. If you upgraded to a more powerful CMMS, you should gain better insight into which assets cost the most to maintain. This data can help you decide whether to repair, replace, or upgrade specific equipment. Energy Usage Some modern CMMS platforms allow you to track energy consumption. Even if yours doesn’t, you can still connect utility data to your maintenance program. Watching energy usage over time helps you spot inefficient equipment or areas where upgrades could save money. Waste Reduction and Sustainability Metrics If your facility has sustainability goals, a CMMS can help track things like reduced paper use, fewer emergency callouts, or lower emissions from equipment. By logging inspections and preventive maintenance, you can also prevent leaks, wasted materials, or environmental hazards. How to Use Dashboards to Visualize Results Dashboards are one of the most powerful tools in any CMMS. They turn raw data into clear charts, graphs, and alerts that help you understand your facility maintenance KPIs at a glance. A good dashboard shows you what’s happening right now, what needs attention, and how your numbers are trending over time. In MPulse, for example, you can set up dashboards to monitor your most important KPIs, such as open work orders, overdue tasks, upcoming preventive maintenance, and asset performance. You can also create custom views for each department or technician. For example, a technician might need to see their daily assignments, while a facility manager might need a high-level view of total costs and workload. Dashboards also help you communicate with leadership. Instead of digging through spreadsheets, you can show them graphs that make it easy to understand improvements or justify budget requests. When used correctly, dashboards turn your CMMS into a real-time decision-making tool. Ready to Improve Your Performance? Tracking the right facility maintenance KPIs is the best way to measure success after upgrading your CMMS. These metrics give you a clear picture of performance, efficiency, and cost savings. They also help you catch problems early and keep your facility running smoothly. Get started. Contact us.

7 Must-Have CMMS Features for Facility Maintenance

Facility maintenance managers have a lot on their plates with keeping buildings safe, systems running smoothly, and budgets under control. The tools used for maintenance have changed over the years. However, so has the technology behind them. That’s why more and more facility maintenance professionals are turning to cloud-based CMMS to simplify their daily tasks and gain better control over their operations. Cloud-Based CMMS for Facility Maintenance Cloud-based CMMS gives maintenance teams the ability to manage every aspect of their operations in one centralized platform. With a cloud CMMS, teams can create, assign, and track work orders, monitor asset performance, and access real-time maintenance data from any location. That means your team can stay up to date whether they’re in the office, on the production floor, or out in the field. This connectivity makes it easier to stay organized, respond quickly to issues, and make data-driven decisions that improve efficiency. Unlike older desktop systems that require manual updates and limit access to a single device, cloud CMMS software is faster, more flexible, and far more reliable. Users can log in from any internet-connected device, ensuring everyone always has the most current information. Modern facility maintenance software streamlines daily maintenance tasks, reduces downtime, and helps extend the lifespan of valuable assets. The result is a more productive team, lower operating costs, and a maintenance operation that runs smoothly and efficiently. Best of all, all your maintenance data is backed by the cloud. CMMS Features for Facility Maintenance If you’re thinking about upgrading, look for these seven must-have CMMS features for facility maintenance. 1. Mobile Work Order Management Paper work orders and clipboards are a thing of the past. With mobile maintenance tools, technicians can receive, update, and close work orders directly from their smartphones or tablets. A good cloud CMMS should allow your team to: Mobile work order management helps keep everyone on the same page, no matter where they are in the facility. It also cuts down on errors caused by lost paperwork or outdated information. 2. Asset Tracking & Barcode Scanning Keeping track of every piece of equipment across multiple buildings can be challenging. That’s where asset tracking comes in. Modern CMMS platforms include tools that let you record and monitor every asset, from HVAC systems to lighting controls and elevators. Barcode or QR code scanning makes this even easier. By scanning a code with a mobile device, technicians can instantly pull up the asset’s full history, including past repairs, manuals, and warranty details. This instant access to maintenance data saves time and reduces mistakes. With accurate asset tracking, facility managers can make better decisions about when to repair or replace equipment, helping extend asset life and reduce costs. 3. Preventive Maintenance Scheduling One of the biggest advantages of a CMMS is scheduling preventive maintenance to stop problems before they happen. A strong preventive maintenance feature automatically schedules inspections, filter changes, lubrication, and other routine tasks based on time, usage, or meter readings. Preventive maintenance ensures nothing slips through the cracks and helps avoid costly breakdowns. It also keeps facilities in compliance with safety and quality standards. With cloud CMMS, all this scheduling happens automatically, and reminders are sent to technicians through mobile alerts. That means less guesswork and fewer unexpected failures. 4. IoT and Software Integration Today’s facilities are becoming smarter thanks to the Internet of Things (IoT) and software integration tools. When your CMMS can connect to these systems, it unlocks powerful capabilities. For example, sensors can send real-time data to CMMS, such temperature, humidity, or vibration readings. The software can then generate alerts or even create work orders automatically when equipment is operating outside of normal conditions. This integration allows facility teams to move from reactive to predictive maintenance, reducing downtime and extending the life of equipment. It also helps optimize energy use and supports sustainability goals. 5. Reporting and Dashboards Data is only valuable when you can see and understand it. Modern facility maintenance software includes reporting tools and dashboards that turn maintenance data into actionable insights. With customizable dashboards, you can monitor key performance indicators (KPIs) such as: These reports help facility managers identify trends, measure team performance, and justify budgets with solid data. In a cloud CMMS, dashboards update in real time, so you always know what’s happening in your buildings. 6. Offline Access and Data Sync Facilities don’t always have perfect Wi-Fi or cell service, particularly in remote sites. That’s why offline access is a critical CMMS feature. The best cloud CMMS solutions allow technicians to keep working even when they’re offline. Your team can update work orders, record notes, and capture photos while disconnected. Once the device reconnects to the internet, all data syncs automatically. Offline functionality ensures maintenance work never stops, no matter where your team is or what the network conditions are like. 7. Scalability and Security Finally, your CMMS should be built to grow with your organization. Whether you manage one building or a portfolio of properties, scalability ensures your system can handle more users, assets, and data without slowing down. At the same time, security must be top priority. Look for a provider that offers encrypted data storage, secure user logins, and regular system backups. Cloud vendors typically provide stronger security than most on-site servers, along with automatic software updates and uptime guarantees. By choosing a cloud CMMS that’s both scalable and secure, you protect your investment and ensure your system stays reliable for years to come. Smart CMMS Features for Facility Maintenance Managers Upgrading to a modern cloud CMMS is one of the smartest moves a facility maintenance manager can make. The right CMMS features can transform how your maintenance team operates. With the right system in place, you’ll reduce downtime, extend asset life, and make data-driven decisions that keep your facilities running efficiently. Ready to explore a cloud CMMS for your facility management needs? Start by listing the features that matter most to your team and look for a platform that helps you grow,

Top 5 Industries That Need CMMS Software

If your organization produces goods or provides a service, or if it operates out of a building, managing maintenance should be one of your top priorities. CMMS software provides tools that help many different types of industries keep everything working properly. Whether it’s machines, equipment, vehicles, buildings, or multiple facilities, CMMS software helps companies organize, plan, and keep track of all their maintenance work. CMMS can save companies time, cut down on costs, and prevent unexpected breakdowns that can cause problems. These five industries rank at the top for CMMS software benefits. Industry #1: Manufacturing In manufacturing, every minute of downtime can translate into thousands of dollars lost. To keep production on schedule and operations efficient, machines must be maintained in peak condition. Strategic maintenance planning not only prevents unexpected breakdowns but also extends the lifespan of equipment, reducing costly repairs and replacements. Quick responses to emerging issues help avoid delays that could disrupt delivery timelines, while well-trained staff ensure safety and consistency on the factory floor. CMMS helps manufacturers with the following. With strong maintenance practices in place, manufacturers can protect their bottom line while ensuring smooth, reliable production. Industry #2: Construction In construction, heavy equipment is the backbone of progress, moving between job sites and powering each phase of a project. But without a solid maintenance strategy, tracking repairs manually can become chaotic and expensive. Scheduled upkeep and regular inspections help prevent equipment failures, ensure safety compliance, and keep timelines intact. Detailed service records support smarter budgeting and repair planning, while well-maintained machinery improves worker safety and reduces costly delays. CMMS also helps with the following. By organizing maintenance across all vehicles and machines, construction teams can reduce downtime, control costs, and keep every job site running smoothly. Industry #3: Healthcare Hospitals and healthcare facilities depend on a wide range of complex equipment to deliver safe, timely, and effective care. When systems fail, whether medical devices or building infrastructure, the consequences can include treatment delays, safety risks, and compliance issues. Regular maintenance ensures reliability, supports regulatory inspections, and helps prevent infections. Fast work order assignment and mobile access to maintenance data allow staff to respond quickly and stay informed across departments and locations. CMMS also helps healthcare organizations with the following. By proactively managing maintenance, healthcare organizations create safer environments and maintain the continuity and quality of patient care. Industry #4: Education Educational institutions from K-12 schools to sprawling university campuses are responsible for maintaining a wide range of facilities, including classrooms, labs, dormitories, and athletic centers. Without a reliable system in place, keeping everything running smoothly can be a major challenge. Regularly scheduled maintenance for HVAC, lighting, and other infrastructure helps prevent unexpected breakdowns. Fast issue reporting enables facility teams to resolve problems before they escalate, while centralized management tools streamline operations across multiple buildings. Maintenance reports also support smarter budgeting and long-term planning. CMMS also helps educational institutions with the following. By staying organized with maintenance, schools and universities can reduce downtime, control costs, and focus more fully on delivering quality education and student support. Industry #5: Government and Public Works Government agencies oversee a wide range of public assets from roads and parks to utilities and buildings, which makes maintenance a complex and critical responsibility. Relying on paper records can slow down operations and create confusion, especially when coordinating across departments. Digital tools in CMMS software streamline the process by enabling clear documentation of repairs, faster response to emergencies, and better visibility into ongoing maintenance. These systems also support transparency, improve budgeting decisions, and help agencies maintain safe, functional public spaces. By adopting modern maintenance systems, public agencies can reduce costs, prevent equipment failures, and deliver more reliable services to the communities they serve. Every Industry Needs CMMS Software Across every industry, good maintenance management helps teams stay organized, work efficiently, and be proactive. It replaces paper logs and spreadsheets with a digital system that tracks assets, schedules tasks, and sends alerts in real time. Whether managing construction equipment, maintaining school buildings, or ensuring hospital safety, good maintenance routines are essential. They help reduce costs, prevent delays, and keep operations running smoothly. Effective maintenance management software isn’t just a tool; it’s a smart solution that makes managing maintenance easier and better for every industry. Have questions? We have answers. Contact us.

How to Choose the Right Work Order Management Software for Your Business

If your business relies on equipment, facilities, or other assets that need maintenance, it’s essential to keep them running smoothly. When machines break down or jobs fall through the cracks, it can cost time, money, and trust. That’s where work order management software can help. CMMS helps track maintenance tasks, manage assets, schedule work, and keep detailed records in one place. But with so many options on the market, how do you choose the right one for your business? This simple guide will help you make a smart, confident choice. What Work Order Management Software Does Work order management software is designed to help you plan, track, and complete maintenance tasks efficiently. Whether you’re managing a manufacturing line, a fleet of vehicles, or a public facility, work order management software ensures that nothing slips through the cracks. A good CMMS platform goes beyond tracking work orders. It also keeps a full history of repairs, tracks spare parts, manages schedules, and even generates reports that help you spot problems early. Instead of relying on paper forms or spreadsheets, everything is stored digitally. As a result, your team can find and update data easily. Seven Steps to Choose the Right Work Order Management Software Step 1: Identify Your Biggest Challenges Before shopping for software, think about your current pain points. Ask yourself: The right CMMS should solve your specific problems. For example, if downtime is your biggest issue, look for a system with strong preventive maintenance tools and automated reminders. If communication is a problem, find one with mobile access and real-time updates. Step 2: Look for the Must-Have Features Not every CMMS offers the same tools. When comparing options, make sure the work order management software includes the following key features: Step 3: Think About Ease of Use Even the most powerful CMMS won’t help if your team finds it confusing. Look for a system with a clean, intuitive interface. Many vendors offer free demos or trials. Take advantage of them. During your trial, test how easy it is to: If your technicians and managers can learn the basics quickly, that’s a great sign. Step 4: Consider Scalability and Support Your needs today may not be the same in a year or two. Choose a CMMS that can grow with your business. Scalable software should allow you to add more users, assets, or sites without major costs or downtime. Also, make sure the vendor offers strong customer support and training resources. Look for flexible help options, online tutorials, and quick response times. Good support can make a huge difference during setup and beyond. Step 5: Compare Pricing and Value Pricing for work order management software can vary widely. Some systems charge per user per month, while others charge a flat fee for unlimited users. There may also be extra costs for setup, training, or advanced features. When comparing prices, don’t just look for the cheapest option. Instead, think about value. How much time, money, and effort will the system save in the long run? A slightly higher cost may be worth it if it improves uptime, reduces waste, and helps your team work smarter. Step 6: Read Reviews and Ask for References Before making a final decision, read user reviews and ask the software vendor for customer references. Find out how other companies in your industry are using the system and what results they’ve seen. Reviews can reveal useful details about real-world performance, such as how reliable the mobile app is or how fast customer support responds. Step 7: Start Small, Then Expand Once you’ve chosen your CMMS, start with a pilot program. Test it in one department or location before rolling it out company-wide. This implementation process helps identify any issues early and gives your team time to adjust. Gather feedback from your technicians, managers, and administrators. Use what you learn to fine-tune your setup before expanding. Choose the Work Order Management Software that Fits Your Business Choosing the right work order management software is an investment in your business’s efficiency and reliability. A well-chosen CMMS can help you prevent breakdowns, lower costs, and keep your operations running smoothly. By taking time to understand your needs, compare features, and test your options, you’ll find a solution that fits your business perfectly. As a result, you can keep your equipment working, your team organized, and your customers happy. Get started today. Contact us.

Best CMMS Software in 2025

CMMS helps maintenance teams plan, track, and improve their operations. It handles everything from preventive maintenance scheduling and work orders to inventory tracking and performance reporting. As a result, your maintenance operations can get tasks done efficiently and easily measure the results. Most quality CMMS platforms include core features like work order management, maintenance scheduling, asset tracking, inventory control, reporting, and mobile access. These tools help teams prevent breakdowns, eliminate backlogs, manage parts, and control costs. The ultimate goal is to streamline operations and reduce downtime. Whether you’re transitioning from spreadsheets or replacing your current system, this in-depth comparison will help you choose the right solution. 1. MPulse CMMS Top Features Biggest Benefits MPulse CMMS is designed to help organizations of all sizes streamline their maintenance operations, improve asset reliability, and reduce downtime. What Do Users Like About MPulse? Users highlight MPulse’s balance between functionality and user-friendliness. The system’s adaptability to different industries and strong reporting tools make it a favorite for organizations seeking both flexibility and depth in their CMMS solution. Many recommend purchasing one of MPulse’s affordable implementation services to streamline the process even further. “MPulse has been instrumental in helping us transition from reactive maintenance to a proactive approach. The scheduling and tracking tools are excellent, and the reporting gives us clear visibility into our maintenance costs.” – James K. on Capterra “What I appreciate most is that MPulse can grow with your organization. It’s easy to start small and add modules or integrations as your needs expand. The support team is also responsive and knowledgeable.” – Verified User in Manufacturing on G2 “MPulse makes it easy to organize maintenance work and asset data. The ability to customize fields and workflows means we can tailor the software to fit how we operate instead of the other way around.” – Sarah M. on G2 Pricing MPulse offers flexible pricing tiers depending on deployment type (cloud or on-premises), number of users, and selected modules. Plans generally start around $49 per user per month, with additional costs for advanced features like predictive maintenance, API access, and enterprise reporting. A free demo and custom quote are available upon request. 2. Limble CMMS Limble CMMS is a cloud-based platform that helps organizations manage and improve their maintenance operations. With an solid interface and a range of practical features, it supports teams across industries in organizing workflows, reducing downtime, and maintaining asset performance. Top Features Why Users Like Limble CMMS Companies like G2, Capterra, Reddit, Software Advice, and more make it easy to hear from software users about their experience. Here are some of the most useful reviews. What Do Users Dislike About Limble CMMS? 3. Fiix CMMS Fiix CMMS is a cloud-based maintenance management platform that integrates AI and machine learning for maintenance efficiency and asset performance. Its interface and scalable design make it a strong choice for small to mid-sized businesses with distributed assets. Top Features What Do Users Like About Fiix? Users report that overall, Fiix is a useful tool for helping organize and execute maintenance and equipment servicing. They also report a good relationship with customer service and overall improved work order coordination across teams. What Do Users Dislike About Fiix? Reviewers note that there is room for improvement in the way the system facilitates communications with work requestors who don’t have user licenses. They also comment on the lack of customizability for some features. Pricing Fiix CMMS uses a tiered pricing structure, beginning with a free plan that covers essential maintenance functions, then expanding to paid tiers with more advanced capabilities. The Basic plan costs $45 per user per month, and the Professional plan is $75, both adding tools such as advanced scheduling, analytics, and reporting. For larger organizations with specialized needs, the Enterprise plan provides customized solutions with pricing available upon request. 4. UpKeep UpKeep positions itself as a mobile-first CMMS built to simplify maintenance and operations management for businesses of all sizes. Its interface and features enable users to manage work orders, track assets, and streamline maintenance activities from both mobile devices and desktops. Top Features What Do Users Like About UpKeep? UpKeep customers report it to be a significant upgrade from paper and manual processes, especially for the cost. They also appreciate its useability and visual appeal. What Do Users Dislike About UpKeep? While UpKeep is rated highly overall, some users report a lack of customizability, bugginess, and technical difficulties with some features. Pricing UpKeep offers a tiered pricing structure based on the number of users and the level of features needed. They do not offer a long-term free plan but do provide a 14-day free trial. Plans range from a “lite” level that includes basic maintenance management tools at $20 per user per month. Advanced options that include predictive maintenance, reporting analytics, and integrations can cost as much as $120 with additional products and add-ons like IoT connectivity for additional fees. 5. MaintainX MaintainX is a mobile-first CMMS that emphasizes the advantages of managing maintenance through its mobile app. It offers an interface and tools for handling work orders, performing inspections, and tracking assets from smartphones or tablets. The platform is geared toward organizations with distributed teams and frontline workers who need real-time access to information and tasks while on the move. Top Features What Do Users Like About MaintainX? MaintainX delivers the basics for its users, including an intuitive interface, real-time communication, and efficient work order management. Many report having a more organized and more mobile operation as a result of using the system. What Do Users Dislike About MaintainX? Smaller teams or startups may find that MaintainX’s pricing is higher for the features offered than some other solutions. Some users report occasional bugs or limited options for customization and integration with other tools. Pricing MaintainX provides four pricing tiers, starting with a free basic plan that includes unlimited work orders and messaging. The Essential plan, priced at $16 per user per month, adds features like recurring work orders and reporting. The Premium plan costs $49 per

Boost Profitability Through Smarter Facility Maintenance Strategies

Facility managers and building maintenance professionals know that one of the most effective ways to improve profitability is by controlling operational costs without compromising service quality. That’s where strategic facility maintenance planning comes into play. Whether you manage a single building or a portfolio of properties, streamlining your operations can lead to significant savings and improved tenant satisfaction. Here are three powerful ways to make your building maintenance more productive, cost-effective, and future-proof. Invest in Energy Efficiency By reducing energy and water consumption, you can lower utility bills and appeal to environmentally conscious tenants. Energy-efficient buildings often command higher rents and longer lease terms, making them a smart investment for property owners and managers. There are two key categories of energy efficiency to consider. Passive Efficiency Passive energy efficiency focuses on infrastructure upgrades that reduce consumption without requiring ongoing effort. Examples include: While these improvements may involve upfront costs, the long-term savings can be substantial. Plus, many regions offer rebates or incentives for green upgrades, further improving your ROI. Active Efficiency Active efficiency involves changing how maintenance tasks are performed. Examples include: These practices not only reduce resource consumption but also extend the life of your equipment. Down the road that saves money on repairs and replacements. Implement CMMS Software CMMS software centralizes all your maintenance activities, from work orders to service requests, into a single digital platform. Here’s how CMMS software can elevate your facility maintenance operations: By implementing CMMS software, property managers gain greater control over their operations, reduce administrative overhead, and improve service delivery. Tenants benefit too, with faster response times and more transparent communication. Establish a Preventive Maintenance Program Fixing things when they break is a costly and inefficient approach. Instead, preventive maintenance (PM) helps you stay ahead of problems before they escalate into expensive emergencies. A well-designed PM program, powered by CMMS software, allows you to: Preventive maintenance reduces downtime, minimizes tenant complaints, and lowers the risk of major repairs. It also helps you forecast expenses more accurately, making it easier to maintain a healthy budget. Smarter Facility Maintenance Strategies Facility maintenance isn’t just about fixing leaks and replacing light bulbs. It’s a strategic function that directly impacts your profitability. By investing in energy efficiency, implementing CMMS software, and establishing a preventive maintenance program, you can control costs, improve service quality, and stay competitive. In a market where tenants expect responsiveness and sustainability, these strategies position your business as a forward-thinking, reliable partner. The time you spend planning today will pay off in smoother operations, happier tenants, and a stronger bottom line tomorrow. Want help getting started? Contact MPulse. Our experience can help you boost your profitability.

Why Investing in Facility Maintenance Services Pays Off

For organizations that own or manage buildings, investing in facility maintenance is often seen as a necessary expense. In reality, however, it’s a powerful long-term investment. When done strategically, maintaining your facilities can significantly reduce costs, extend asset life, and increase overall operational efficiency. The return on investment (ROI) from professional facility maintenance services goes far beyond avoiding breakdowns. It also contributes directly to safety, sustainability, and profitability. In this post, we’ll explore why investing in facility maintenance services pays off, how to measure ROI, and how tools like CMMS software make maintenance operations smarter and more cost effective. How Facility Maintenance Pays Off Facility maintenance keeps a building and its assets in peak working condition. These maintenance tasks include preventive maintenance, routine inspections, equipment repairs, and strategic asset management. The purpose of a facility maintenance program is to ensure safety, compliance, and efficiency while minimizing downtime and extending the life of valuable equipment. Improving facility maintenance services can transform daily operations and strengthen long-term ROI. The True Cost of Neglecting Building Maintenance It’s tempting to delay maintenance to save money in the short term. However, this approach almost always costs more later. Reactive maintenance can result in unplanned downtime, expensive emergency repairs, and even safety issues. Consider an HVAC system that receives no preventive care. A neglected air filter might lead to overworked motors, poor air quality, and higher energy bills. What could have been a simple, low-cost fix becomes a major repair or full system replacement. Studies consistently show that preventive facility maintenance costs far less than emergency repairs. According to industry benchmarks, every dollar spent on preventive maintenance can save up to five dollars in future repair and replacement costs. That’s a substantial ROI that directly impacts an organization’s bottom line. How Facility Maintenance Services Improve ROI Facility maintenance services deliver measurable financial benefits when executed strategically with CMMS software. Here’s how they increase ROI: The Long-Term Benefits of Proactive Facility Maintenance Investing in facility maintenance services is an investment in your organization’s future. By using CMMS software tools, organizations shift from a reactive approach to a proactive, data-driven facility maintenance strategy. As a result, you not only reduce downtime but also get the transparency needed to justify maintenance budgets and demonstrate ROI to stakeholders. A proactive maintenance strategy delivers lasting value by: When maintenance is planned and managed effectively, every dollar spent contributes to long-term performance, safety, and savings. Measuring ROI in Facility Maintenance To measure the ROI of facility maintenance, consider both direct and indirect benefits. Direct ROI includes measurable savings from reduced repair costs, extended equipment life, and lower energy use. Indirect ROI comes from improved uptime, fewer safety incidents, and enhanced tenant or employee satisfaction. By tracking metrics like work order completion times, maintenance costs per asset, and downtime hours, facility managers can clearly demonstrate how their maintenance programs contribute to the organization’s overall financial performance. Investing in Facility Maintenance = Strategic Advantage Too often, facility maintenance is treated as a background function rather than a strategic advantage. But when managed correctly, it becomes a key driver of efficiency, safety, and profitability. The ROI from investing in facility maintenance services is undeniable: fewer breakdowns, lower costs, longer-lasting assets, and improved compliance. Whether you manage a single building or an entire portfolio, prioritizing maintenance today means protecting your assets, your people, and your bottom line for years to come. Get started today. Contact us.

How CMMS in Facility Maintenance Improves Safety and Compliance

Keeping a building safe and up to code is one of the most important jobs for any facility manager. Whether it’s a school, hospital, office, or factory, people rely on these spaces to be safe, clean, and in good working order. But with so many schedules, inspections, and regulations, it can be tough to stay on top of everything. CMMS helps facility maintenance teams plan, track, and manage maintenance work. It doesn’t just save time. It also makes a big difference when it comes to safety and compliance. Let’s break down how. CMMS Helps Make Facility Safety a Priority Accidents often happen when small issues go unnoticed. Using CMMS in facility maintenance helps prevent issues by keeping track of maintenance tasks and scheduling reminders for maintenance teams. For example, if air conditioning unit in a school isn’t cleaned and serviced on time, it could spread dust, mold, or even break down in the middle of a heatwave. With CMMS, the system automatically creates a work order for routine cleaning and alerts the maintenance staff before the problem grows. By keeping equipment in good shape, facilities reduce risks like: When everything functions properly, the whole building becomes a safer place for the people inside. Staying Ahead of Compliance Every building has rules to follow. These regulations and compliance standards come from government agencies, safety boards, and industry groups. They might include fire safety codes, health inspections, or workplace safety standards from the Occupational Safety and Health Administration (OSHA). Failing to meet these standards can lead to big problems, like fines, lawsuits, or even being shut down. More importantly, it can put lives at risk. But CMMS can help. CMMS stores inspection dates and makes sure nothing is missed. Instead of relying on sticky notes, paper calendars, or memory, CMMS keeps all inspection dates in one place. It automatically schedules the next due date so teams don’t forget important tasks like fire alarm tests, elevator inspections, or water quality checks. You can keep records of all maintenance work for proof during audits. When inspectors ask for evidence, a CMMS makes it easy to pull up detailed reports. Every work order includes the date, technician’s name, and notes on the task. This process creates a digital paper trail that shows the facility followed the rules. Maintenance software sends alerts when compliance checks are due. CMMS doesn’t wait for someone to remember. It sends notifications ahead of time. That way, safety checks, certifications, and license renewals are never a surprise. Your team can track safety equipment tests. Items like fire extinguishers, sprinklers, and emergency lighting all have strict testing schedules. CMMS tracks when each test was last done and when it’s due again, making sure nothing slips through the cracks. Your organization can standardize procedures. With CMMS, managers can create step-by-step instructions for compliance tasks. As a result, every technician follows the same process, reducing mistakes and keeping work consistent across the whole team. CMMS provides digital access to regulations. Some CMMS platforms allow teams to upload compliance checklists or manuals directly into the system. That way, staff have the correct guidelines on hand while doing inspections. You can create easy-to-share reports. When leadership or inspectors need updates, CMMS can generate reports with a few clicks. These reports show proof of compliance and highlight areas that need improvement. Better Organization = Fewer Mistakes CMMS keeps everything in one central system. Work orders, inspection results, safety checks, and equipment manuals are all stored digitally. Everyone on the team can see what needs to be done and when. This ability reduces confusion and mistakes. For example, instead of three different people thinking someone else handled a fire extinguisher inspection, the CMMS shows exactly who did it, when it was done, and whether it passed or failed. Quick Response to Emergencies Even with great preventive maintenance, emergencies sometimes happen. When they do, a fast response makes all the difference. CMMS helps teams react quickly by allowing staff to submit emergency work orders from their phones, showing technicians where equipment is located and how to fix it, and tracking response times so managers can see how quickly problems are resolved. For example, if a water pipe bursts in an office, staff can immediately log it in the CMMS. The system alerts the right technician, who can see the repair history and get the job done faster. That prevents bigger damage and keeps the workplace safe. Creating a Culture of Accountability One of the biggest benefits of using a CMMS is accountability. When safety and compliance tasks are logged, tracked, and reported, everyone knows what they are responsible for. Managers can see which tasks are overdue, which ones are complete, and who handled them. Instead of rushing through jobs or skipping steps, technicians know their work matters to the bigger picture. Over time, this creates a culture where safety is not just a checklist, it’s part of daily operations. Long-Term Benefits of CMMS in Facility Maintenance Using a CMMS for safety and compliance isn’t just about avoiding accidents and fines today. It also builds long-term benefits for facilities. Benefit #1: Lower costs from fewer emergency repairs and legal issues. Emergency breakdowns are expensive. Not only do they require urgent labor and parts, but they often cause downtime that disrupts daily operations. On top of that, failing inspections or breaking safety rules can lead to fines or lawsuits. CMMS helps prevent these costs by scheduling preventive maintenance and keeping facilities in compliance, saving money over the long run. Benefit #2: Stronger reputation with staff, customers, and inspectors. People notice when a building is safe, clean, and well-maintained. Employees feel valued when they work in a safe environment, customers trust businesses that care about safety, and inspectors appreciate when a facility is organized and compliant. A good reputation builds confidence and strengthens relationships with everyone who interacts with the facility. Benefit #3: More reliable equipment that lasts longer and works better. Every piece of equipment has a lifespan, but proper