Calculating your CMMS return on investment (ROI) offers powerful support for either buying your first CMMS or upgrading to a more modern platform. By automating key processes, simplifying work order management, and enhancing data analysis, CMMS platforms help shift maintenance operations from reactive to proactive. To calculate CMMS ROI, you measure the financial benefits of its use against its implementation and operational costs.

Here’s how to start:

Table of Contents

1. Identify the Benefits of CMMS

Step 1 identifies the benefits of CMMS. You’ll add up the savings your organization will experience. These advantages typically include the following.

- Reduced Equipment Downtime: A CMMS enables preventive maintenance, which reduces breakdowns and keeps machinery running smoothly.

- Lower Maintenance Costs: By scheduling routine maintenance, the need for emergency repairs and the costs associated with them can be minimized.

- Extended Asset Lifespan: Regular maintenance leads to prolonged equipment life.

- Increased Productivity: Less downtime translates to more uptime and productivity.

- Inventory Management: Reducing excess inventory or stockouts for maintenance parts can save money. Quantify these benefits based on your organization’s specific data or industry averages, estimating the financial impact over a set period (e.g., yearly savings).

2. Calculate Costs of CMMS

Next, you’ll calculate the costs of your CMMS. This step involves simply adding up what you spend to get the software up and running. Start with the invoice or quote from your vendor. Add up the following line items.

- Software Purchase or Subscription: This may be a one-time license fee or a recurring subscription cost.

- Implementation and Setup: Includes installation, initial data entry, and configuration.

- Training: Costs for training employees to use the software effectively.

- Ongoing Maintenance and Support: Any recurring fees for updates, support, or maintenance of the CMMS. Total these costs to get a clear picture of the investment.

3. CMMS Return on Investment Formula

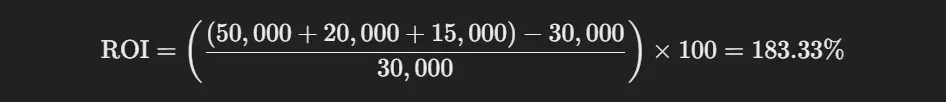

Once you have both the quantifiable gains and costs, use the standard ROI formula:

This calculation gives you the ROI as a percentage, showing how much value the CMMS generates in relation to its cost.

4. Track Additional KPIs

To validate the ROI further, monitor Key Performance Indicators (KPIs) such as mean time between failures (MTBF), mean time to repair (MTTR), maintenance compliance, and work order completion rates. Improvements in these metrics can affirm the ongoing value of the CMMS.

Example CMMS Return on Investment Calculation:

Suppose a company experiences $50,000 in savings from reduced downtime, $20,000 from lower maintenance costs, and $15,000 from inventory optimization within a year. If the total cost for implementing and maintaining the CMMS in that year is $30,000, the ROI would be:

This means the CMMS delivers 183.33% in returns over its costs for that year.

Calculating CMMS return on investment is a simple yet compelling way to show its value. By illustrating the cost savings and productivity gains a CMMS can deliver, this calculation makes a strong case for investment. Furthermore, it can be the foundation for establishing your maintenance team as a critical strategic partner in achieving broader organizational goals, moving beyond routine maintenance to supporting long-term efficiency and growth.

MPulse can help you calculate your CMMS Return on Investment. Contact us to get started.