Scheduled maintenance, also called preventive maintenance, is performed to reduce the possibility of equipment or asset failure.

Using CMMS software to schedule preventive maintenance is the easiest and fastest way to get these tasks done—and done on time.

Preventive maintenance software will generate a schedule of PM tasks, making it simpler to follow the manufacturer’s guidelines. As a result, these schedules and inspections help spot issues before they occur.

Table of Contents

Preventive Maintenance Software Solutions and Features

CMMS software enables you to schedule maintenance intervals based on time, operating hours, or part condition—triggering a work order just before the point when system inefficiencies or failures begin to occur.

Use of preventive maintenance software ensures equipment is properly calibrated and lubricated when it needs to be. Properly maintained assets also perform more efficiently, use less energy, and fail less often—extending their usable life.

How To Schedule Preventive Maintenance Work Orders in MPulse

Step 1. Choose Maintenance Intervals

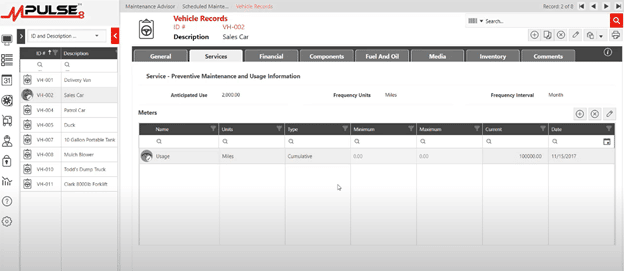

If you want to use a meter-based schedule, you need to have a meter associated with the service section of the asset. If you want to create a time-based schedule, skip to Step 2.

In this example, the asset is a vehicle and the meter is mileage.

- Choose the asset record on the equipment that you want to schedule preventive maintenance.

- Click on the Services tab.

- Set Anticipated Usage, Frequently Units, and Frequency Interval.

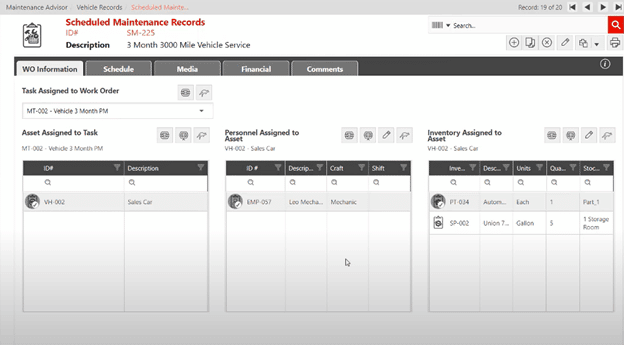

Step 2. Connect Asset to Scheduled Maintenance Record

- Set up a scheduled maintenance record with Asset Assigned to Task, Personnel Assigned to Asset, and Inventory Assigned to Asset.

- Click on the Services tab.

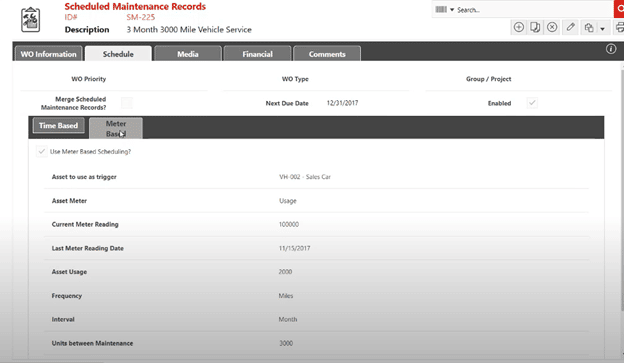

Step 3. Schedule Maintenance

- Click Time Based or Meter Based.

- Click the Edit button (pencil) in the top right corner.

- For a meter-based schedule, select the Asset and Asset Meter.

Step 4. Choose Units Between Maintenance

- Select the Units between Maintenance. In the example, we used 3000 miles, which MPulse then calculates against the Current Meter Reading and Anticipated Usage, and then estimates the next due date.

When a maintenance team establishes and regularly performs PM tasks that contribute to the upkeep of assets, an organization may be able to sidestep serious problems that arise as a result of neglect, as well as delay more expensive maintenance.

Learn more about how MPulse can help you with scheduled maintenance. Contact us.