Home > Resources > Learning Center > What is EAM Software?

What is EAM Software?

With continuous advancements in CMMS, EAM Software has finally met its match! Whether you opt for a CMMS or EAM solution, understanding the key differences is essential.

Table of Contents

What Is Enterprise Asset Management (EAM) Software?

Most organizations begin their digital asset management journey with a Computerized Maintenance Management System (CMMS). These platforms are commonly used to schedule recurring preventive maintenance (PM) tasks, manage inventory, and catalog equipment information. CMMS also provides valuable Key Performance Indicators (KPIs), helping managers identify opportunities for improving maintenance efficiency, reducing downtime, and lowering costs.

However, as organizations grow and the number of assets under management increases, a CMMS may no longer be sufficient. Larger enterprises require more robust systems to track complex asset data such as warranties, downtimes, and depreciation. This is where Enterprise Asset Management (EAM) software comes into play, offering organizations a comprehensive solution for managing the entire lifecycle of their assets—from acquisition to disposal.

It’s important to note that the distinction between CMMS and EAM is becoming less clear. Many modern CMMS platforms now incorporate many of the features traditionally found in EAM software, blurring the lines between the two.

Key Features of EAM Software

While EAM software can be customized to meet the specific needs of an organization, most platforms include the following core features:

Asset Lifecycle Management: The primary function of EAM software is to optimize the efficiency and cost-effectiveness of an organization’s assets throughout their entire lifecycle, from acquisition to disposal.

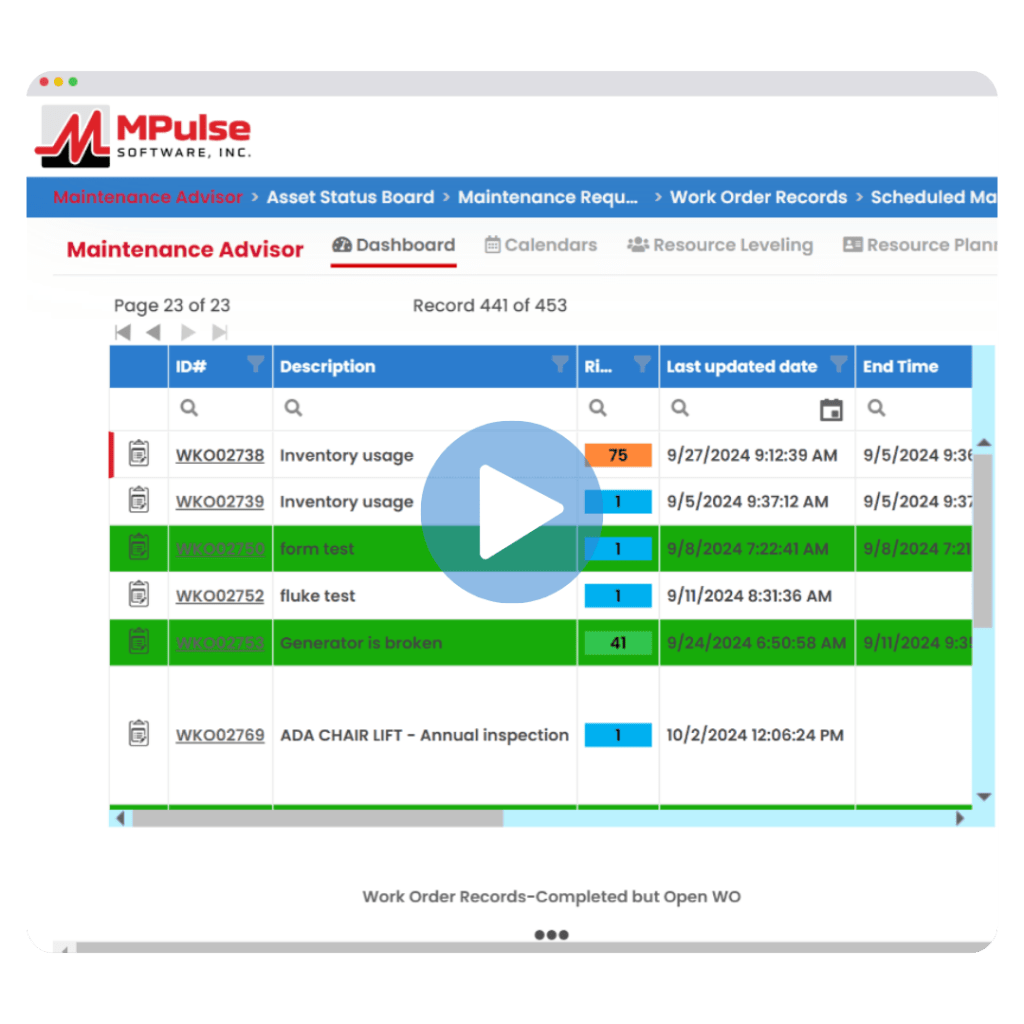

Work Order Management: EAM software allows managers to create, assign, and track work orders once a problem is identified. This helps maintain an overview of upcoming PM tasks, ensuring that nothing is overlooked.

Inventory/Maintenance, Repair, and Operations (MRO) Materials Management: MRO costs often represent a significant portion of an organization’s procurement budget. EAM software gives managers full control over the inventory procurement process, ensuring they can efficiently manage these critical resources.

Labor Management: HR departments can use EAM software to manage the assessment, training, and certification of maintenance personnel. Many systems also include features for talent management and scheduling.

Contract Management: EAM software provides tools for creating and managing service contracts with employees, vendors, partners, and customers, ensuring that service agreements are adhered to.

Financial Management: EAM software enables organizations to access detailed financial data related to asset management, supporting more accurate accounting, budgeting, and spending. When integrated with other financial systems, it provides a comprehensive view of asset-related costs.

Reporting and Analytics: EAM software generates detailed reports that cross-reference data from various departments. This helps analyze asset performance, identify breakdown trends, and address issues before they escalate.

What differentiates EAM software from basic CMMS is its ability to track an asset’s entire lifecycle—from acquisition to disposal—while also integrating financial data to optimize long-term asset-related expenses. On the other hand, traditional CMMS platforms primarily focus on monitoring asset conditions to improve maintenance decisions. However, modern CMMS solutions like MPulse Software now offer many of the same functionalities as EAM software.

The 4 Phases of Asset Lifecycle Management

As previously noted, EAM software enables organizations to manage every phase of an asset’s lifecycle. The four key phases of asset lifecycle management are:

Design and Specify

EAM software offers valuable insights through performance and maintenance reports for all assets. These reports are essential for designing an asset acquisition strategy that maximizes utility while minimizing costs. After identifying the ideal asset, you can document the specifications for your procurement team.

Procure and Build

EAM software streamlines the procurement process, including creating purchase orders and tracking new assets post-delivery. Once an asset is installed, the software records vital information such as commission dates, asset values, locations, preventive maintenance schedules, and assigned technicians.

Operate and Maintain

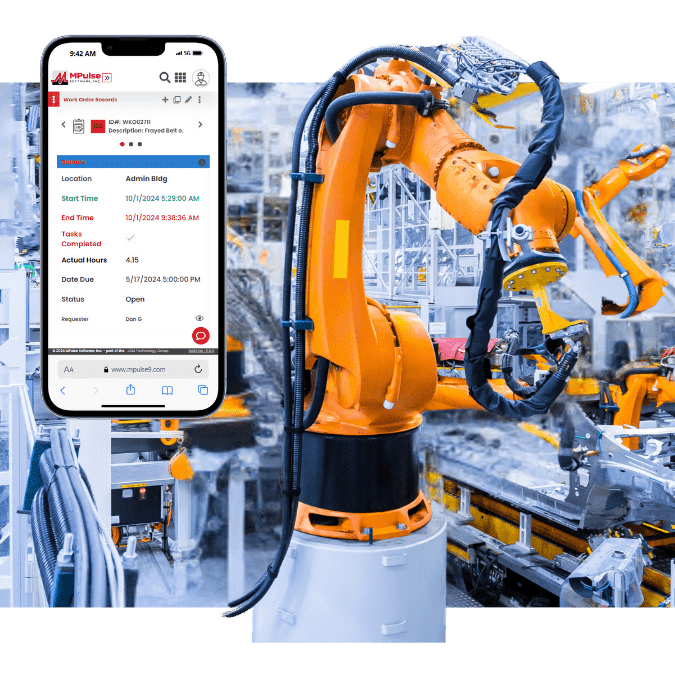

The software continuously records and analyzes asset activity based on input from users and maintenance personnel. By attaching barcodes to assets, users can quickly scan them to create work orders if a breakdown occurs. Technicians can also access historical and current work order data from their mobile devices while on-site, improving response times.

Decommission and Dispose

At the end of an asset’s lifecycle, financial and asset management teams review key data such as depreciation and maintenance costs to determine whether to continue operations or decommission the asset. EAM software archives records of disposed assets for future auditing purposes.

What’s the Difference Between EAM Software and CMMS Software?

At first glance, the differences between EAM Software and CMMS software may seem minimal—both help organizations shift from a reactive to a proactive maintenance strategy by automating tasks such as maintenance scheduling, work orders, and inventory management.

The key difference lies in their scope. A CMMS primarily focuses on the maintenance aspect of an asset’s lifecycle—managing it while the asset is in operation. It helps ensure assets remain in optimal working condition by tracking and addressing maintenance needs.

EAM software, on the other hand, manages the entire lifecycle of an asset—from creation or procurement to disposal. EAM is typically used by larger organizations with multiple users across various locations and includes features like lifecycle planning, budgeting, and financial integration. In short, EAM provides a much broader view of asset management, helping organizations coordinate resources like finances, materials, skills, and information to meet their strategic goals.

MPulse for Enterprise Asset Management

EAM software has caught the attention of industry leaders. That’s because it maximizes the predictability and profitability of equipment or facilities. It also identifies ways to improve those performance indicators.

You might think that only large organizations can afford a tool this powerful. However, MPulse customers of all sizes are reaping the benefits of standardizing maintenance across sites or locations.

MPulse Means Happy Customers

“The features and price made MPulse the right choice and the service has been excellent.”

John Smith

Maintenance Supervisor, Penn State University

“You can tailor the program to fit the needs of your particular facility. The performance of the software is overall very good.”

Maintenance Manager

Reed College

“I started using MPulse in March of 2006 using v6. The upgrade to v7 has been a smooth and easy transition offering more of the features that are needed by my sites.”

Facilities Manager

IKEA US West Inc.

“It certainly has simplified keeping track of what we do and how we do it.”

Director of Engineering

Real Estate Services, Northwell Health

“MPulse has been with us every step of the way as our business expanded. Consistently outstanding service.”

Facilities Coordinator

Distribution Center, Chicos FAS, Inc.

“When you use pencil and paper, it takes hours. It takes a lot of time to get a result, where it only takes minutes in software like MPulse.”

Executive Administrative Assistant

St. George Steel