6 Ways a CMMS Can Lower Education Operational Costs

Controlling education operational costs with CMMS software goes beyond mere task management; it serves as a safeguard for a community’s investment in education. Yet finances remain a primary concern, as always. With tightening budgets, many educational facilities have resorted to a reactive approach, fixing only what breaks in order to comply with financial constraints. But […]

10 Signs It’s Time to Upgrade Your Maintenance Software

If you haven’t researched CMMS software lately, you might be surprised at how much things have changed. Maintenance software consistently gets more powerful—and more flexible—while also often becoming more affordable. So, how do you know when it’s time to upgrade your CMMS software? Look for one of these ten signs. Sign #1: Your Organization Has […]

5 Mistakes to Avoid When Implementing a New CMMS

Managing your maintenance operations with a CMMS establishes visibility. You can learn what’s going right, when you need to make improvements, and where you’re spending your dollars. However, CMMS success requires careful planning. Here are five common mistakes that we’ve seen organizations make, and how to avoid them. #1: Fail to lead One of the […]

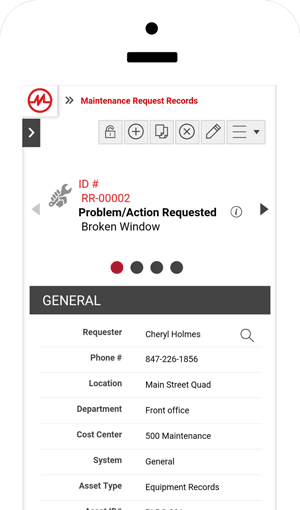

When to Use a CMMS App, Part 2

Last time we talked about why many users don’t need a CMMS app. However, sometimes a CMMS app is the best solution. If your job involves working off site or in areas with low connectivity, a CMMS app can make your job a lot easier. With smartphones and tablets, you can capture information on the […]

How to Use Reliability Centered Maintenance (RCM) to Build Efficiencies

Globalization and economic pressures are forcing companies to build efficiencies wherever possible. As a result, the reliability of assets will become even more important than ever. What is Reliability Centered Maintenance? Reliability centered maintenance (RCM) defines maintenance as the means to maintain an asset’s functions in a defined operating context. Therefore, companies can focus resources […]

How to Calculate Downtime

Calculating asset downtime offers new insights into your maintenance operations, and how you can make improvements. But how do you calculate downtime? And what can you do with that information? Here’s what you need to know. What Is Equipment Downtime? Downtime refers to any period when a system fails to perform its primary function. For […]

How To Get The Most Out Of Your Scheduling Software

Service scheduling software always tops the list of essential maintenance management tools. Every major asset has a recommended maintenance schedule. CMMS makes it simple to schedule services based on time or usage, so the maintenance team knows what needs to happen and when. Benefits of Scheduling Software The biggest benefit of service scheduling software is […]

How Important is Your CMMS Support Team?

MPulse customers have a secret weapon in their journey to CMMS success—our customer support team. These professionals help new users successfully implement their new CMMS software, as well as continue to use it effectively. We’re proud of our MPulse Support Team and their accomplishments. Here’s what we think you should know about them. Three Ways […]

How Your Maintenance Team Can Get the Most Out of Your Part Inventory Management Software

Like many maintenance professionals, you’ve decided it’s time to start or expand your part inventory management system. However, you want to get the most out of your investment. So, what should you do to get started? Meet yourself where you’re at. Just Getting Started Maybe your organization doesn’t do any part inventory management for maintenance. […]

Signs Your Company Is Ready for Predictive Maintenance

We’ve discussed why you might not need a predictive maintenance program, and how to do it right if you do. But, how do you know if your company is ready for a predictive maintenance strategy? Start by looking for these signs your company is ready for predictive maintenance. Sign #1: An Effective Preventive Maintenance Program […]