Service scheduling software always tops the list of essential maintenance management tools. Every major asset has a recommended maintenance schedule. CMMS makes it simple to schedule services based on time or usage, so the maintenance team knows what needs to happen and when.

Benefits of Scheduling Software

The biggest benefit of service scheduling software is automating preventive maintenance scheduling and work order management. However, you can use it for much more, including…

- Tracking work orders

- Viewing progress

- Automating communication

- Creating reports

- Handling service requests

- Managing inventory/supplies

- Documenting asset repair history

Service scheduling is the first step towards improving productivity for your entire maintenance operations. Here’s how to get the most out of your software.

Set Up Scheduled Maintenance

Maintenance managers have been scheduling maintenance for decades. Technological advances, however, have automated the service scheduling process, making it more efficient and sustainable.

Start by setting up scheduled or preventive maintenance tasks. Your software will generate a schedule of PM tasks, making it simpler to follow the manufacturer’s guidelines. As a result, these schedules and inspections help spot issues before they occur.

CMMS software enables you to schedule maintenance intervals based on time, operating hours, or part condition—triggering a work order just before the point when system inefficiencies or failures begin to occur. (See our previous blog post for more information on how to do that in MPulse.)

Convert Scheduled Task to a Work Order

When a task is due, you’ll want the software to convert it to a work order. Luckily MPulse makes this easy.

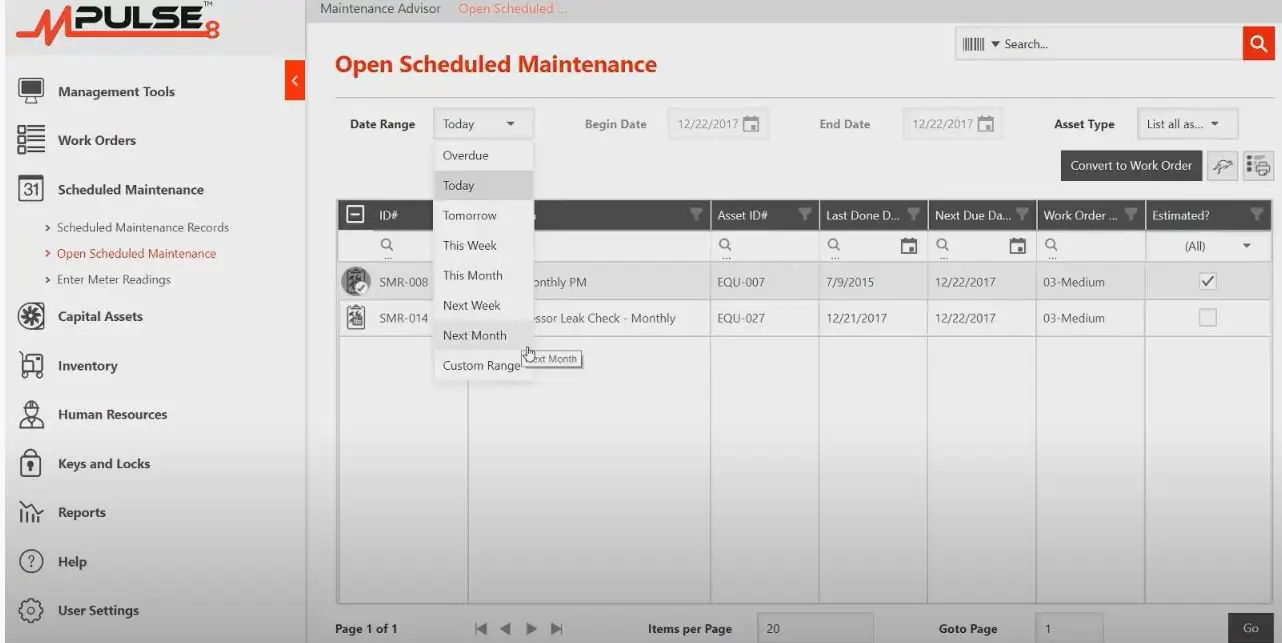

- Go to Scheduled Maintenance in the main menu.

- Click on Open Scheduled Maintenance.

- Choose the date range you want: Overdue, Today, Tomorrow, This Week, This Month, Next Week, Next Month, or Custom Range.

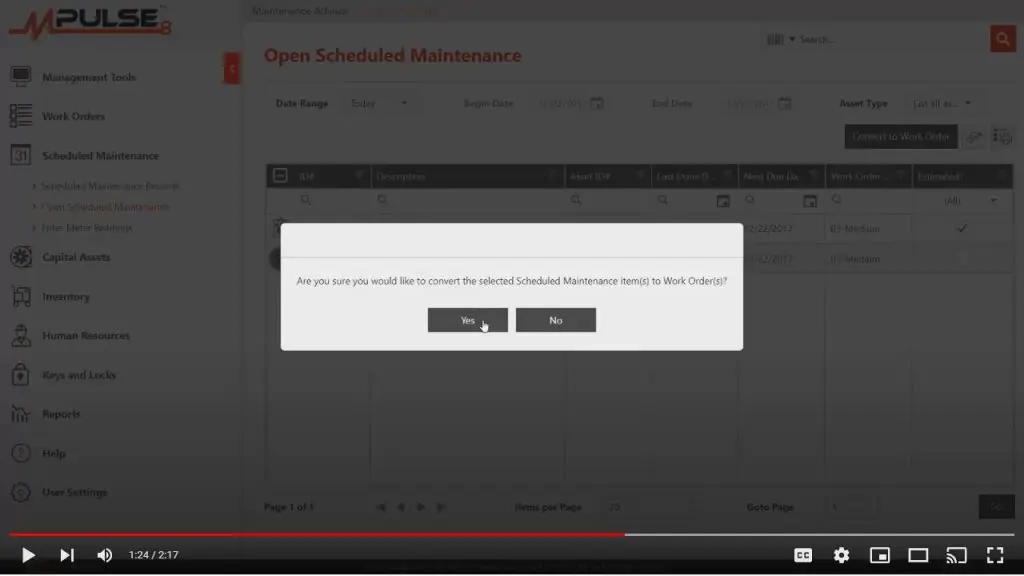

- Select the records to convert and click on Convert to Work Order

- Click Yes to confirm

Now you have an open work order ready for your technician.

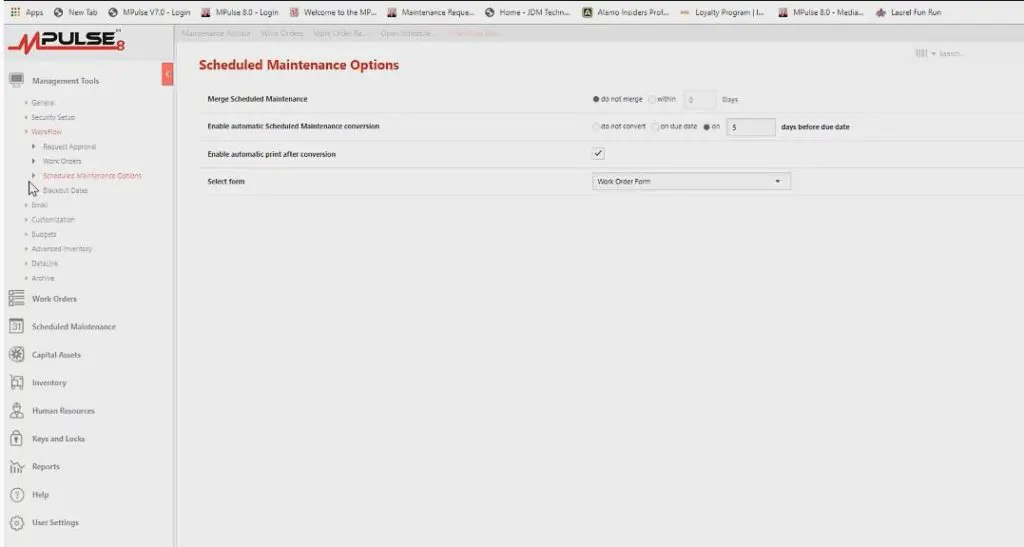

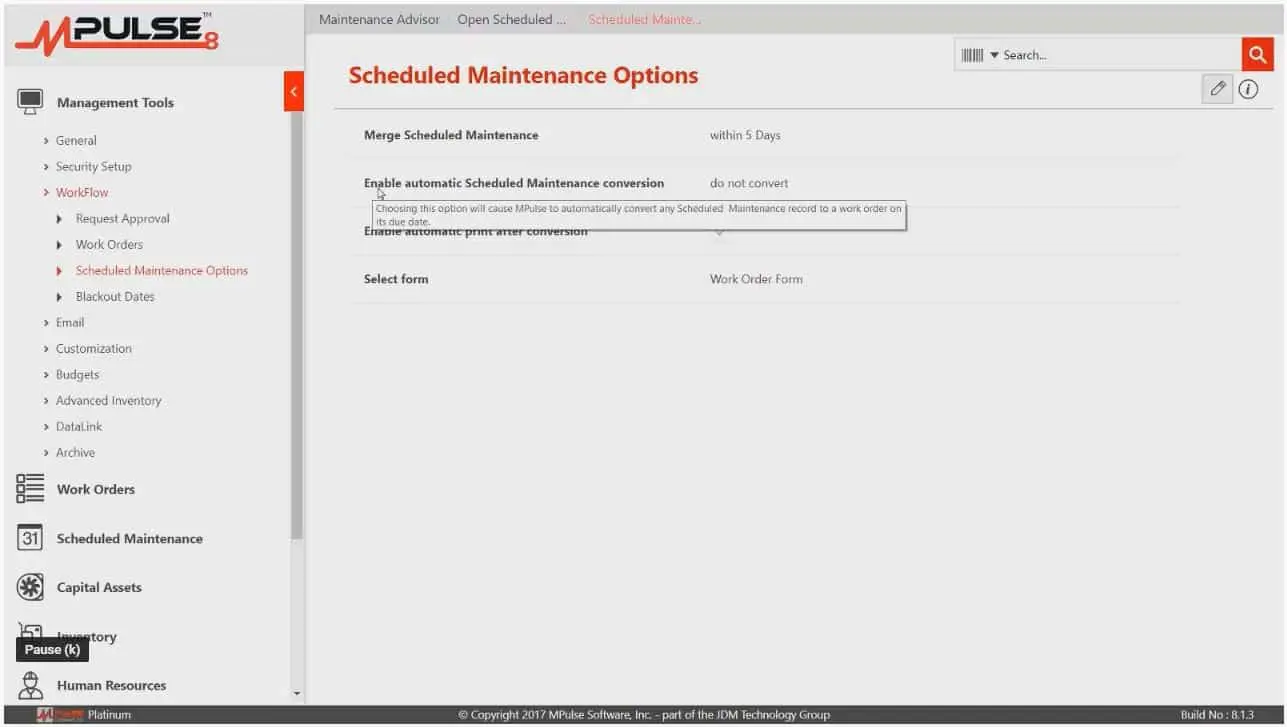

Automate This Process

While that process is simple, you can make it even easier by automating it. When a scheduled task is due, MPulse will automatically convert it to a work order.

- From the main menu, choose Workflow / Scheduled Maintenance Options

- Click Enable Scheduled Maintenance conversion

Note that you can choose to convert scheduled tasks automatically on the due date or any number of days before the due date. These changes will impact all scheduled maintenance records.

Print Work Orders

If your team members still receive printed copies of work orders, you can also make this process more efficient in MPulse.

- From the main menu, choose Workflow / Scheduled Maintenance Options

- Click the box for Enable Automatic Print after Conversion

Black Out Dates

Most companies close on specific days or major holidays. MPulse makes it easy to set blackout dates that will adjust due dates and work order conversion accordingly.

- From the main menu, choose Workflow / Scheduled Maintenance Options / Blackout Dates

- Click the Add icon

- Enter your preferred date ranges

The blackout date has been added to the list. MPulse will use blackout dates to push any scheduled maintenance record that comes due on those days to the next available date.

Properly maintained assets perform more efficiently, use less energy, and fail less often, which also extends their usable life. When a maintenance team establishes and regularly performs tasks that contribute to the upkeep of assets, an organization may be able to sidestep serious problems that arise as a result of neglect as well as delay more expensive maintenance.

Contact us to learn more.