Home > What is Lockout Tagout?

Simplify Lockout Tagout Compliance with MPulse CMMS

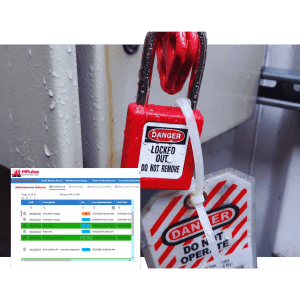

Lockout Tagout (LOTO) is a vital safety protocol that prevents accidental equipment start-up during maintenance, ensuring worker safety and regulatory compliance. This guide will help you understand the importance of LOTO and how to implement it effectively in your facility.

Importance of Lockout Tagout for Facilities

The U.S. Occupational Safety and Health Administration (OSHA) mandates that all facilities operating potentially dangerous machinery implement Lockout Tagout procedures. LOTO protects technicians by requiring the temporary disabling of equipment energy sources and preventing the accidental activation of machines during hazardous conditions.

Turning off machinery alone does not guarantee safety. For instance, compressed air and electricity remain hazardous even when equipment appears off. OSHA estimates that proper Lockout Tagout procedures prevent around 50,000 injuries and 120 fatalities annually in the United States. Despite its importance, LOTO is among the most commonly violated OSHA standards.

Maintenance technicians should apply LOTO when installing, repairing, cleaning, lubricating, and unjamming equipment. Unfortunately, many facilities neglect to use LOTO for routine servicing of essential production equipment. Industries such as oil and gas, maritime, construction, and agriculture often rely on alternative safety measures instead of Lockout Tagout.

Table of Contents

What is Lockout Tagout (LOTO)?

Lockout Tagout (LOTO) is a critical safety procedure designed to ensure maintenance technicians fully shut down hazardous equipment before performing repair or maintenance work. This process involves using specialized lockout devices that prevent machinery from energizing during servicing. Additionally, it requires turning off energy sources—such as electricity, natural gas, steam, pressurized water, and compressed air—to enhance safety. Warning tags are also posted to deter unauthorized personnel from interacting with the equipment.

Types of Hazardous Energy Controlled by Lockout Tagout

Lockout Tagout procedures protect against various types of hazardous energy, including:

Mechanical Energy: Generated by moving parts like robotic arms, saw blades, and crushing mechanisms. Accidental contact can lead to severe injuries.

Hydraulic Energy: Found in machinery using pressurized hydraulic oil. Proper LOTO procedures involve releasing this pressure before maintenance.

Pneumatic Energy: Similar to hydraulic energy but involves compressed air. Releasing stored air pressure is essential before servicing.

Chemical Energy: Involves managing chemicals that could be accidentally released, such as gases from diesel generators that emit nitrogen and sulfur oxides.

Thermal Energy: Comes from heat sources like natural gas, coal, and nuclear power, commonly found in mining and power generation industries.

The 6 Essential Steps of Lockout Tagout

While procedures can vary by organization, the general Lockout Tagout process includes these six steps:

Preparation

Identify all hazardous energy sources and specific hazards associated with the equipment.

Shutdown

Power off and lock out the machinery. Notify affected employees about the shutdown timeline.

Isolation

Isolate the machine from its energy source (e.g., closing valves or flipping circuit breakers).

Lockout Tagout Application

Attach LOTO devices, clearly identifying the authorized employee performing the procedure.

Stored Energy Check

Ensure no residual energy remains by safely releasing or restraining any stored energy.

Verification

The last step is to confirm the equipment is fully de-energized and safe for maintenance.

Only authorized personnel should remove LOTO devices once maintenance is complete. If equipment cannot be physically locked out due to operational constraints, warning tags must be used to enforce safety precautions.

Key Components of an Effective Lockout Tagout Program

A comprehensive Lockout Tagout program should outline:

Types of hazardous energy related to facility assets

Procedures for isolating and de-energizing equipment

Required energy-isolating devices

Authorized maintenance personnel

Tools necessary for each step

Steps for removing lockout devices and restarting equipment

Training for authorized personnel

Verification procedures for complete isolation

Facilities should regularly review and update their LOTO programs as they expand and acquire new assets to ensure ongoing employee safety.

Streamlining Lockout Tagout with MPulse

Proper Lockout Tagout procedures safeguard employees from hazardous energy exposure and help facilities comply with OSHA regulations. Failure to implement LOTO endangers workers and exposes organizations to costly penalties.

Using a digital Computerized Maintenance Management System (CMMS) like MPulse Software simplifies sharing and enforcing Lockout Tagout procedures across teams. Implementing LOTO workflows through MPulse Software ensures that safety protocols are accessible and standardized for all maintenance personnel.

MPulse Means Happy Customers

“The features and price made MPulse the right choice and the service has been excellent.”

John Smith

Maintenance Supervisor, Penn State University

“You can tailor the program to fit the needs of your particular facility. The performance of the software is overall very good.”

Maintenance Manager

Reed College

“I started using MPulse in March of 2006 using v6. The upgrade to v7 has been a smooth and easy transition offering more of the features that are needed by my sites.”

Facilities Manager

IKEA US West Inc.

“It certainly has simplified keeping track of what we do and how we do it.”

Director of Engineering

Real Estate Services, Northwell Health

“MPulse has been with us every step of the way as our business expanded. Consistently outstanding service.”

Facilities Coordinator

Distribution Center, Chicos FAS, Inc.

“When you use pencil and paper, it takes hours. It takes a lot of time to get a result, where it only takes minutes in software like MPulse.”

Executive Administrative Assistant

St. George Steel