Manufacturing: Siemens Building Technologies Bolsters Plant Communications

Find out how this $100-billion per year, 362,000-employee global behemoth uses MPulse to monitor its manufacturing assets in real time using MPulse Asset Status Board.

In the three years since the company implemented MPulse CMMS software, the Siemens Building Technologies Group has acheived:

- Work Order Completion Rate of 85-90% per month

- Preventative Maintenance Completion Rate of 100% per month

Siemens attributes much of the success to the strong relationship between the companies, which is built on collaboration.

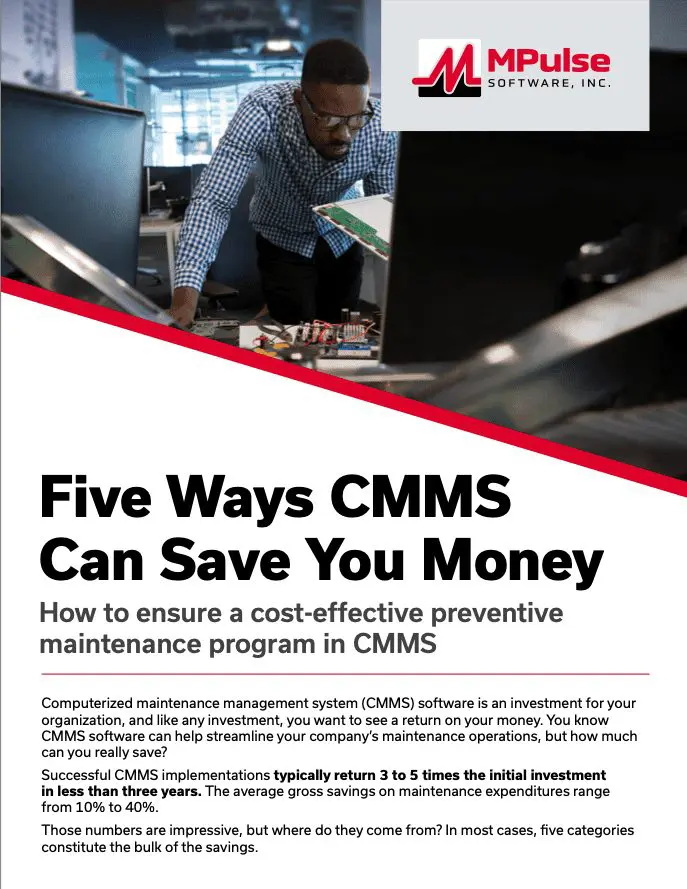

Five Ways CMMS Can Save You Money

Show me the money!

Computerized maintenance management software (CMMS) is an investment for your organization, and like any investment, you want to see a return on your money.

You know computerized maintenance management software can help streamline your company’s maintenance operations, but how much can you really save?

Successful CMMS implementations typically return 3 to 5 times the initial investment in less than three years. The average gross savings on maintenance expenditures range from 10% to 40%.

Those numbers are impressive, but where do they come from? In most cases, five categories constitute the bulk of the savings.

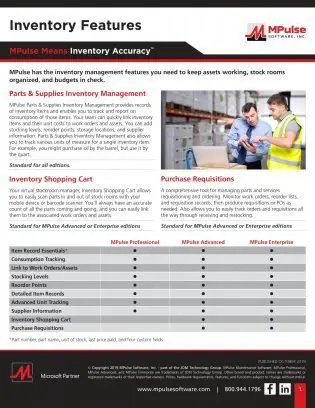

Inventory Features Datasheet

MPulse has the inventory management features you need to keep assets working, stock rooms organized, and budgets in check.

Features include…

- Item record essentials (part number, part name, unit of stock, last price paid, and four custom fields)

- Consumption tracking

- PartLink

- Stocking levels

- Reorder points

- Detailed item records

- Advanced unit tracking

Whether you need simple tracking of spare parts consumption or advanced inventory features, MPulse has the solution for you.

Predictive Maintenance Data Alone is Not Enough

What if you could predict when your equipment was starting to break down and fix it before it actually fails?

It’s possible with the powerful combination of predictive maintenance (PdM) data and computerized maintenance management system (CMMS) software.

While PdM tools provide powerful data, that information’s value is limited without the context provided by CMMS software.

The combination of PdM data and a CMMS solution provides the most comprehensive view of your equipment.

Learn 5 important questions CMMS can help you answer to boost the effectiveness of your PM program.

MPulse Reset Program Datasheet

Sometimes maintenance management feels like a moving target. It’s easy to get redirected away from the CMMS implementation that was once your priority.

You had big plans for using MPulse CMMS software to improve efficiencies, reduce costs, and get better visibility of maintenance histories. But your day-to-day responsibilities can distract you from realizing your vision.

It’s time to push the Reset button on your MPulse implementation.

The MPulse Reset Program covers all the phases of a successful process review. It will help you adapt, re-focus, and reconfigure your workflows and benchmarks, and then determine where adjustments can be made.

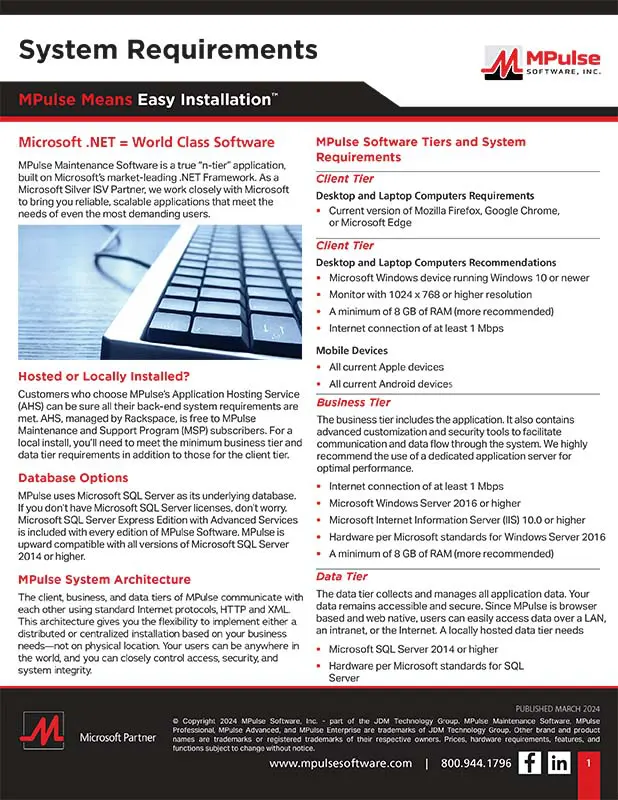

MPulse System Requirements Datasheet

MPulse Maintenance Software is a true “n-tier” application, built on Microsoft’s market-leading .NET Framework.

As a Microsoft Silver ISV Partner, we work closely with Microsoft to bring you reliable, scalable applications that meet the needs of even the most demanding users.

The client, business, and data tiers of MPulse communicate with each other using standard Internet protocols, HTTP and XML.

This architecture gives you the flexibility to implement either a distributed or centralized installation based on your business needs—not on physical location.

Your users can be anywhere in the world, and you can closely control access, security, and system integrity.

Multi-site Implementation Program Datasheet

Putting a CMMS/EAM solution in place across multiple locations can seem daunting.

MPulse Multi-site Implementation Program (MSIP) gets you through planning, data migration, training, and “go-live” day on each site so your processes, reporting needs, data types, and data imports are the same at each location.

Then we provide tailored recommendations and follow-up so you can measure your progress against goals.

MSIP is designed to accelerate your software implementation and reduce your ramp-up time,

Discover how MPulse can help you minimize disruptions and achieve a faster return on your CMMS investment.

Multisite Connector Datasheet

Until recently, anyone seeking maintenance software had to choose between feature richness with scalability—and something they could afford.

Large ERP vendors and other Fortune 500 software companies wanted us to believe they had the only solutions capable of meeting your demanding requirements.

They didn’t tell us their “Enterprise Asset Management” (EAM) packages were just scaled-up versions of the CMMS software we really needed, with features we’d never use.

And they didn’t tell us we’d be paying 3 to 4 times the price, while suffering through lengthy implementations manned by expensive consulting teams.

The MPulse Enterprise Management Suite provides a better solution. Get the details on this framework that enables large organizations to scale MPulse across numerous, geographically dispersed locations, while maintaining control and visibility enterprise-wide.

Condition-Based Maintenance (CBM) Datasheet

How much does your company stand to lose from unanticipated repairs and the resulting losses in productivity?

If, like most businesses, you count on scheduled PMs alone to prevent breakdowns, the losses could be greater than you think.

Predictive maintenance based on the true conditions of assets can help save your company thousands and thousands of dollars.

MPulse Condition-Based Maintenance (CBM) is a software addon that keeps tabs on the actual state of your critical assets by recording the output of any meters and gauges on that asset.

When an asset’s condition changes outside of specified ranges, MPulse lets you know immediately, so you can react to prevent breakdowns before they happen.

Every day your assets are trying to tell you something—are you ready to listen?

Inventory Shopping Cart Datasheet

Do items seem to appear on your storeroom shelves without getting properly received?

Do spare parts disappear or miss getting linked to work orders?

On busy days, tracking what’s coming and going from your inventory room can seem impossible.

MPulse Inventory Clerk will help you never miscount again.

Discover why MPulse Inventory Clerk is the easiest and most reliable way to track your inventory.